Home Page

ꄲ

Semiconductor

ꄲ

Wafer laminating machine

ꄲ

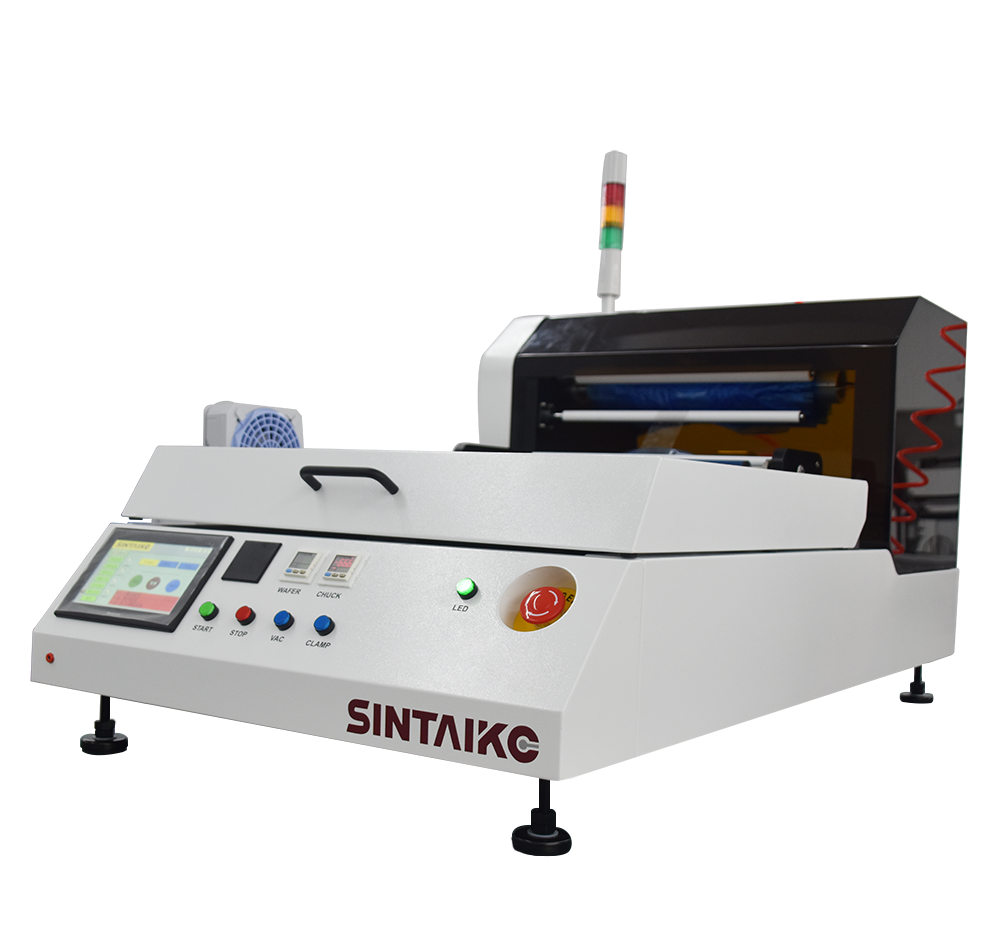

SINTAIKE STK-7121 Semi-automatic substrate cutting and laminating machine

SINTAIKE STK-7121 Semi-automatic substrate cutting and laminating machine

STK-7121 semi-automatic substrate cutting and laminating machine features:

- 8 "/12" bearing ring is applicable and can also support customization; Optimized design of square bearing ring

- Advanced anti-static roller film pasting technology

- Automatic film feeding and pasting

- Manual substrate loading and unloading

- Manual film cutting

- Blue film and UV glue film are supported.

- Program control based on PLC, with touch screen

- Configure the emergency stop button

- Tri-color lighthouse and buzzer, which are used to monitor the operation status.

Performance of STK-7121 semi-automatic substrate cutting and laminating machine;

| Wafer yield |

≥99.9% |

| Film pasting quality | No bubbles (excluding dust particle bubbles) |

| Hourly capacity | ≥ 80 Frame |

| Product replacement time |

≤ 15 minutes |

Specification parameters of STK-7121 semi-automatic substrate cutting and laminating machine;

| Substrate size |

200(L) x 50(W) ~ 250(L) x 70( W)mm |

| Substrate thickness |

0.1~1mm,warping (Warpage) < 8 mm |

| Substrate type | QFN, DFN, LGA, etc. |

| Membrane type |

Blue film or UV film Width: 230~400 mm Length: 100m Thickness: 0.05 ~ 0.2mm. |

| Frame bearing ring |

Customers can customize the standard of square bearing ring. 8 "and 12" Square Bearing Rings |

| Film sticking principle | Anti-static roller film pasting |

| Film pasting accuracy |

X-Y:+/- 0.5mm ;Θ:+/- 0.5 |

| Film pasting tray | Replaceable contact table with antistatic coating; Or a silica gel tabletop or a porous metal tabletop. |

| Loading and unloading mode | Manual placement and removal of base plate/bearing ring |

| static control | Anti-static coating wafer table/anti-static film roller/anti-static ion generator device |

| Cutting system | Manual track type direct cutting knife |

| Base plate/bracket positioning | Universal marking/spring locating pin |

| control unit | Based on PLC control with 5.7 "touch screen. |

| Safety protection | Configure the emergency stop button |

| Power supply voltage | Single-phase alternating current 220V,6A |

| compressed air | 5 kg of clean and dry compressed air with a flow rate of 2 cubic feet per minute. |

| machine casing | White plastic-sprayed metal shell |

| volume | 680mm (width) * 1110mm (depth) * 870mm (height) |

| net weight | 110 kg |