Home Page

ꄲ

Semiconductor

ꄲ

Wafer laminating machine

ꄲ

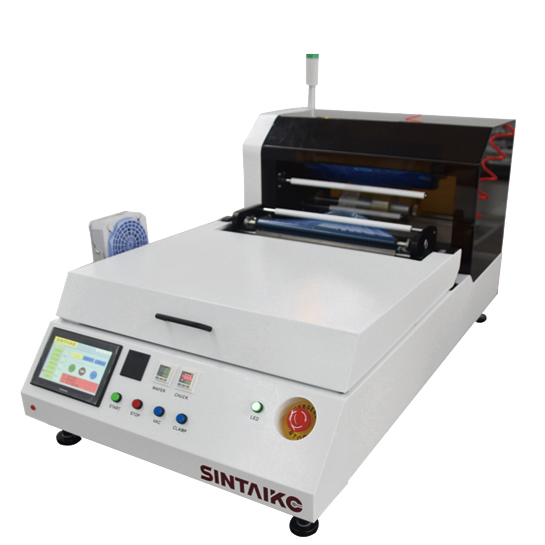

SINTAIKE STK-5020 semi-automatic wafer thinning and film tearing machine Wafer Detaper

SINTAIKE STK-5020 semi-automatic wafer thinning and film tearing machine Wafer Detaper

Characteristics of STK-5020 semi-automatic film tearing machine after wafer thinning:

- Desktop

- Suitable for 4 "-8" wafers.

- easy to operate

Performance of STK-5020 semi-automatic film tearing machine after wafer thinning;

| Wafer yield |

≥99.9% |

| Tearing film quality | No lobes |

| Hourly capacity |

≥80 wafers |

|

MTBF |

>168 hours |

|

MTTR |

<1 hour |

| down time |

<3% |

| Product replacement time |

≤ 5 minutes |

Specification parameters of STK-5020 semi-automatic film tearing machine after wafer thinning;

| Wafer size | 4 "-8" wafer |

| Wafer thickness | 150 ~750 microns |

| Wafer type | Silicon, gallium arsenide or other materials |

| Tearing film type |

Tearing tape Width: 38 ~ 100mm Length: 100m |

| Tearing angle | < 45 degrees, and can be adjusted from 5 degrees to 45 degrees. |

| Wafer platen |

General (integrated) Teflon anti-static coating contact table; The platen can be heated: room temperature ~ 100℃; |

| Loading and unloading mode | Manual placement and removal of wafers |

| Antistatic control | Teflon anti-static coating contact table; Electrostatic ion removing fan |

| Wafer positioning | Pneumatic pin positioning |

| control unit | Based on PLC control and equipped with 7 "touch screen; |

| Drive unit | Servo motor drive |

| Safety protection | Configure the emergency stop button |

| Power supply voltage | Single-phase alternating current 220V, 10A |

| compressed air | 5 kg of clean and dry compressed air with a flow rate of 100 liters per minute. |

| machine casing | White plastic-sprayed metal shell |

| volume | 670 mm (width) *1180 mm (depth) *1000 mm (including lamp height) |

| net weight | 125 kg |